Boeing Workers’ Strike Poses New Challenges for Aerospace Suppliers

LATEST news

-

Microsoft & Nvidia Announce Up to $15 Billion Investment in AnthropicNews

Microsoft & Nvidia Announce Up to $15 Billion Investment in AnthropicNews -

AI Innovation Helps Couple Conceive After 19-Year StruggleNews

AI Innovation Helps Couple Conceive After 19-Year StruggleNews -

Tesla Launches Cheaper Model Y and Model 3 to Boost SalesNews

Tesla Launches Cheaper Model Y and Model 3 to Boost SalesNews -

Google Merger of Android and ChromeOS Confirmed — Qualcomm CEO Confirms He's Experienced It in OperationNews

-

Microsoft Unveils In-House AI Models to Challenge OpenAINews

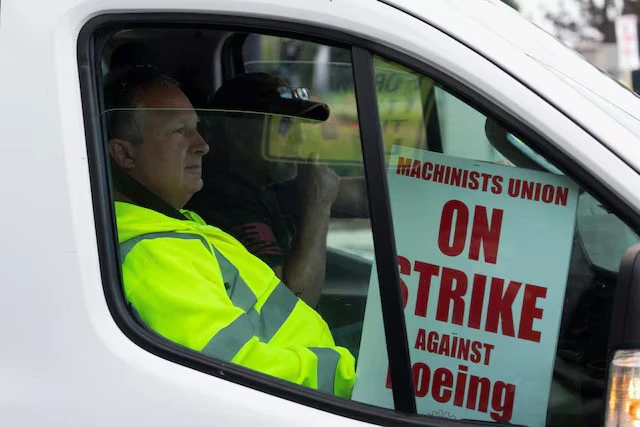

A recent 64% rejection of Boeing’s latest contract offer by West Coast factory workers has increased concerns for suppliers such as Independent Forge, an Orange County California based family business. The more than 33 thousand Boeing employees in the United States who joined the strike since September 13, the conflict carries risks for the stability of aerospace parts suppliers.

Andrew Flores, president of Independent Forge, said that if the strike keeps on, the company might have to scale down its production to three days from the current five to hold off on costs and remain competitive enough to keep its skilled workers. While select employees have been laid off, this possibility is unappealing because the remaining 22 workers are highly specialized and necessary to meet demand in the future once manufacturing reoccurs.

The strike has already been deeply felt in Boeing’s commercial jet assembly lines and has propagated through its broad supply chain network of giant plants to small workshops. The aerospace firms, which are grappling with effects from the COVID-19 crisis in the first place, are now ordering fewer parts, and that presents fresh challenges for their suppliers who have spent money to expand capacity in expectation of a rebound.

That is how factors such as labor unrest and how small suppliers, including Independent Forge, will respond will determine Boeing’s ability to regain production lost in several months. The situation identified the relevance of the aerospace supply chain and the difficulties arising from industrial actions.